- Home

- About us

- Products

- Laminar Airflow Manufacturers in Chennai

- Biosafety Cabinet Manufacturers in Chennai

- Fume Exhaust Hood in Chennai

- Air Shower Manufacturers in Chennai

- Powder Containment Booths

- Pass Box

- Fan Filter Units

- Garment Cabinets

- UV Sterile Chamber

- Positive Pressure Module

- PCR Work Station

- OT Laminor Air Flow

- Modular Cleanrooms

- Laboratory Table

- Contact us

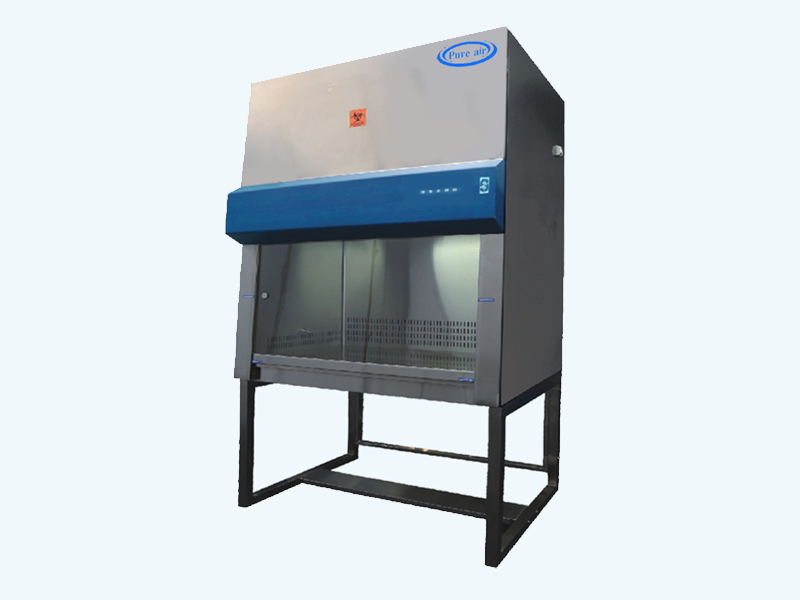

Biosafety Cabinet Manufacturers in Chennai

We are a leading Biosafety Cabinet Manufacturers in Chennai, All model Biosafety Cabinets such as Class II Type A1, Class II Type A2, Class II Type B1, Class II Type B2, Class III are available.

1, Biosafety Cabinet – Class II Type A1

“Pureair” Biosafety Cabinet Class II Type A1 is designed for protection of operator, product and environment from pathogenic agents and microorganisms transmitted in respiratory way and also for creation of a bacterial dust free air environment. It has a common plenum from which 30% of air is exhausted, and 70% re-circulated to the work area as the downflow. Type A cabinets exhaust air directly back to the laboratory, and they may contain positive pressure contaminated plenums. When toxic chemicals must be employed as an adjunct to microbiological processes, these cabinets should not be used. Exhaust HEPA filtration only removes airborne aerosols including biohazards, and not chemical fumes.

The Class II Type A1 has the positively-pressurized contaminated plenum bordering the ambient environment, and therefore is less safe than the Class II Type A2 that has a negative pressure surrounding the positively pressurized contaminated plenum. In case there is a leakage on the positive plenum, the leaking aerosol will be pulled by the negative pressure back to the positive plenum, and it will not leak out. Because of the safety issue, the Type A1 design is now considered obsolete. In the A1 cabinet, about 70% of air from the positive plenum is recirculated as downflow, and the remaining All Class II biological safety cabinets type A1 is suitable for work with microbiological agents assigned to biosafety levels 1, 2 and 3.

Working Area – Stainless Steel IS 304 Grade Satin Finish

| 1 | Product | Biosafety Cabinet – Class II- Type A1 |

| 2 | Air balancing | 70% recirculation.30% exhaust |

| 3 | Protection | Product & personnel & environmental protection |

| 4 | Cleanliness level | ISO class 5 as per ISO 14644-1 |

| 5 | Average Airflow | Inflow Velocity Minimum 0.45 m/s ( 90 FPM) at 8” front opening |

| Velocity | Down Velocity 0.30 m/s ( 65 FPM) | |

| 6 | Noise level | 60 db on A scale |

| 7 | Light Intensity | Minimum 900 lux inside the working area at ambient zero |

| 8 | MOC | Main Body – Galvanized Iron with PU coated / Stainless Steel – Satin Finish Working Area – Stainless Steel IS 304 Grade Satin Finish |

| 9 | Supply Filter | HEPA Filter having EU 13 rating with suitable size. . |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 10 | Exhaust Filter | HEPA Filter having EU 13 rating with suitable size. |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 11 | Pre Filter | “Pureair” make, EU 4 rating with suitable size. |

| Efficiency | 90% down to 10 Microns. | |

| 12 | Noise Level | Less than 70 db ‘A’. |

| 13 | Vibration Level Instrumentation | Minimum. |

| 14 | Magnehelic Differential Pressure Gauge | 01 No. (make : Dwyer, USA) with each unit (To measure differential pressure across the supply HEPA filter). |

| 15 | Motor Blower Assembly | Statically & Dynamically balanced with suitable rating and size. (Induction motor with centrifugal blower) A Mounting unique spring suspension system to take care of vibration and noise. |

| 16 | 3 Pins Switch & Socket | 15 AMPS – 1 set in each unit. |

| 17 | Other Switches | On/Off switches for motor blower & CFL lights. |

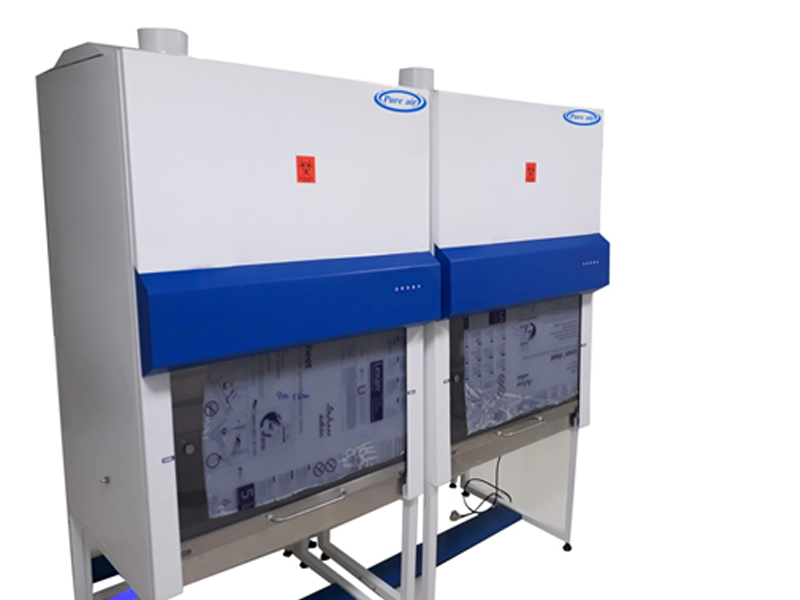

2, Biosafety Cabinet – Class II Type A2

“Pureair” Biosafety Cabinet Class II Type A2 is designed for protection of operator, product and environment from pathogenic agents and microorganisms transmitted in respiratory way and also for creation of a bacterial dust free air environment. It has a common plenum from which 30% of air is exhausted, and 70% re-circulated to the work area as the down flow. Type A cabinets exhaust air directly back to the laboratory, and they may contain positive pressure contaminated plenums. When toxic chemicals must be employed as an adjunct to microbiological processes, these cabinets should not be used. Exhaust HEPA filtration only removes airborne aerosols including biohazards, and not chemical fumes.

The Class II Type A1 has the positively-pressurized contaminated plenum bordering the ambient environment, and therefore is less safe than the Class II Type A2 that has a negative pressure surrounding the positively pressurized contaminated plenum. In case there is a leakage on the positive plenum, the leaking aerosol will be pulled by the negative pressure back to the positive plenum, and it will not leak out. Because of the safety issue, the Type A1 design is now considered obsolete. In the A2 cabinet, about 70% of air from the positive plenum is recirculated as down flow, and the remaining All Class II biological safety cabinets A2 is suitable for work with microbiological agents assigned to biosafety levels 1, 2 and 3.

| 1 | Product | Class II Biosafety Cabinet –Type A2 |

| 2 | Air balancing | 70% recirculation.30% exhaust |

| 3 | Protection | Product & Personnel & Environmental protection |

| 4 | Bio safety Level | Bio safety Level 1 , 2 & 3 |

| 5 | Exhaust Requirement | Return to Laboratory or Thimble Ducting Only |

| 6 | Cleanliness level | ISO class 5 as per ISO 14644-1 |

| 7 | Average Airflow | Inflow Velocity Minimum 0.45 m/s ( 90 FPM) at 8” front opening |

| 8 | Velocity | Down Velocity 0.30 m/s ( 65 FPM) |

| 9 | Noise level | 60 db on A scale |

| 10 | Light Intensity | Minimum 900 lux inside the working area at ambient zero |

| 11 | MOC | Main Body – Galvanized Iron with PU coated / Stainless Steel – Satin Finish Working Area – Stainless Steel IS 304 Grade Satin Finish |

| 12 | Supply Filter | HEPA Filter having EU 13 rating with suitable size. Efficiency 99.99% down to 0.3 Microns. |

| 13 | Exhaust Filter | HEPA Filter having EU 13 rating with suitable size. Efficiency 99.99% down to 0.3 Microns. |

| 14 | Pre Filter | “Pureair” make, EU 4 rating with suitable size. Efficiency 90% down to 10 Microns. |

| 15 | Noise Level | Less than 70 db ‘A’. |

| 16 | Vibration | Level Minimum. Instrumentation |

| 17 | Magnehelic Differential Pressure Gauge | 01 No. (make : Dwyer, USA) with each unit (To measure differential pressure across the supply HEPA filter). Statically & Dynamically balanced with suitable rating and size. |

| 18 | Motor Blower Assembly | (Induction motor with centrifugal blower) A Mounting unique spring suspension system to take care of vibration and noise. |

| 19 | 3 Pins Switch & Socket | 15 AMPS – 1 set in each unit. |

| 20 | Other Switches | On/Off switches for motor blower & CFL lights |

3, Biosafety Cabinet – Class II Type B1

“Pureair” Biosafety Cabinet Class II Type B1 has a common plenum from which 70% of air is exhausted, and 30% re-circulated to the work area as the down flow.

Type B1 cabinets also have a dedicated exhaust feature that eliminates re-circulation when work is performed towards the back within the interior of the cabinet. Toxic chemicals employed as an adjunct to microbiological processes should only be employed if they do not interfere with work when re-circulated in the down flow.

.

| 1 | Product | Bio safety Cabinet – Class II Type B1 |

| 2 | Air balancing | 30% recirculation, 70% exhaust |

| 3 | Protection | Product & Personnel & Environmental protection |

| 4 | Bio safety Level | Bio safety Level 1 , 2 & 3 |

| 5 | Exhaust Duct Requirement | Hard Duct Only |

| 6 | Control Plenum surrounded by | Negative Plenum |

| 7 | Cleanliness level | ISO class 5 as per ISO 14644-1 |

| 8 | Average Airflow | Inflow Velocity – Minimum 0.45 m/s ( 90 FPM) at 8” front opening |

| Velocity | Down Velocity – 0.30 m/s ( 65 FPM) | |

| 9 | Noise level | 60 db on A scale |

| 10 | Light Intensity | Minimum 900 lux inside the working area at ambient zero. |

| 11 | MOC Main Body – | Galvanized Iron with PU coated / Stainless Steel – Satin Finish |

| Working Area – | Stainless Steel IS 304 Grade Satin Finish | |

| 12 | Supply Filter | HEPA Filter having EU 13 rating with suitable size. |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 13 | Exhaust Filter | HEPA Filter having EU 13 rating with suitable size. |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 14 | Pre Filter | Pureair” make, EU 4 rating with suitable size |

| Efficiency | 90% down to 10 Microns. | |

| 15 | Noise Level | Less than 70 db ‘A’. |

| 16 | Vibration Level Instrumentation | Minimum. |

| 17 | Differential Pressure Gauge | Magnehelic Gauge – 01 No. (make : Dwyer, USA) with each unit (To measure differential pressure across the supply HEPA filter). Motor Blower Assembly Statically & Dynamically balanced with suitable rating and size. |

| 18 | Supply & Exhaust | (Induction motor with centrifugal blower) A Mounting unique spring suspension system to take care of vibration and noise. |

| 19 | 3 Pins Switch & Socket | 15 AMPS – 1 set in each unit. |

| 20 | Other Switches | On/Off switches for motor blower & CFL lights. |

| 21 | Microprocessor Control | Airflow display and UV Interlocking and Low airflow Alarm and Supply & Exhaust filter Fail |

4, Biosafety Cabinet – Class II Type B2

Pureair” Biosafety Cabinet Class II Type B2 all inflow and down flow air is exhausted after HEPA filtration to the external environment without recirculation within the cabinet. Type B2 cabinets are suitable for work with toxic chemicals employed as an adjunct to microbiological processes under all circumstances since no re-circulation occurs. In theory, Type B2 cabinets may be considered to be the safest of all Class II biological safety cabinets since the total exhaust feature acts as a fail-safe in the event that the down flow and / or exhaust HEPA filtration systems cease to function normally. However, Class II Type B2 cabinets are, in practice, difficult to install, balance and maintain.

| 1 | Product | Bio safety Cabinet – Class II Type B2 |

| 2 | Air balancing | 0% recirculation.100% exhaust |

| 3 | Protection | Product & Personnel & Environmental protection |

| 4 | Bio safety Level | Bio safety Level 1 , 2 & 3 |

| 5 | Exhaust Duct Requirement | Hard Duct Only |

| 6 | Control Plenum surrounded by | Negative Plenum |

| 7 | Cleanliness level | ISO class 5 as per ISO 14644-1 |

| 8 | Average Airflow | Inflow Velocity – Minimum 0.45 m/s ( 90 FPM) at 8” front opening |

| Velocity | Down Velocity – 0.30 m/s ( 65 FPM) | |

| 9 | Noise level | 60 db on A scale |

| 10 | Light Intensity | Minimum 900 lux inside the working area at ambient zero |

| 11 | MOC Main Body – | Galvanized Iron with PU coated / Stainless Steel – Satin Finish |

| Working Area – | Stainless Steel IS 304 Grade Satin Finish | |

| 12 | Supply Filter | HEPA Filter having EU 13 rating with suitable size. |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 13 | Exhaust Filter | HEPA Filter having EU 13 rating with suitable size. |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 14 | Pre Filter | “Pureair” make, EU 4 rating with suitable size. |

| Efficiency | 90% down to 10 Microns. | |

| 15 | Noise Level | Less than 70 db ‘A’. |

| 16 | Vibration Level Instrumentation | Minimum. |

| 17 | Differential Pressure Gauge | Magnehelic Gauge – 01 No. (make : Dwyer, USA) with each unit (To measure differential pressure across the supply HEPA filter). |

| Motor Blower Assembly | Statically & Dynamically balanced with suitable rating and size. | |

| 18 | Supply & Exhaust | (Induction motor with centrifugal blower) A Mounting unique spring suspension system to take care of vibration and noise. |

| 19 | 3 Pins Switch & Socket | 15 AMPS – 1 set in each unit. |

| 20 | Other Switches | On/Off switches for motor blower & CFL lights. |

| 21 | Microprocessor Control | Airflow display and UV Interlocking and Low airflow Alarm and Supply & Exhaust filter Fail |

5, Biosafety Cabinet – Class III

Pureair” Biosafety Cabinet Class III provides an absolute level of safety, which cannot be attained with Class I and Class II cabinets. All Class III cabinets are usually of welded metal construction and are designed to be gas tight.

Work is performed through glove ports in the front of the cabinet. During routine operation, negative pressure relative to the ambient environment is maintained within the cabinet. This provides an additional fail-safe mechanism in case physical containment is compromised. On all Class III cabinets, a supply of HEPA filtered air provides product protection and prevents cross contamination of samples. Exhaust air is usually HEPA filtered and incinerated.

Alternatively, double HEPA filtration with two filters in series may be utilized. Materials are transferred into the cabinet using a pass-through unit installed at the side of the work area. Class III cabinets usually exhaust air back to the laboratory; however, air may also be exhausted via a dedicated ductwork system to the external environment. When a dedicated ductwork system is employed, they are also suitable for work employing toxic chemicals as an adjunct to microbiological processes. All Class III biological safety cabinets are suitable for work with microbiological agents assigned to biosafety levels 1, 2, 3 and 4. They are frequently specified for work involving the most lethal biological hazards.

| 1 | Product Pureair” | Bio safety Cabinet Class III |

| 2 | Air balancing | 0% recirculation.100% exhaust |

| 3 | Protection | Product & Personnel & Environmental protection |

| 4 | Bio safety Level | Bio safety Level 1 , 2 , 3 & 4 |

| 5 | Exhaust Duct Requirement | Inside the room / Hard Duct Only |

| 6 | Control Plenum surrounded by | Negative Plenum |

| 7 | Cleanliness level | ISO class 5 as per ISO 14644-1 |

| 8a | Negative Pressure | Pressure differential between chamber and environment , Closed >0.5” WC |

| 8b | Front Sash | Airtight construction with Glove Port Arrangement |

| 9 | Noise level | 60 db on A scale |

| 10 | Light Intensity | Minimum 900 lux inside the working area at ambient zero |

| 11 | MOC Main Body – | Galvanized Iron with PU coated / Stainless Steel – Satin Finish |

| Working Area – | Stainless Steel IS 304 Grade Satin Finish | |

| 12 | Supply Filter | HEPA Filter having EU 13 rating with suitable size. |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 13 Exhaust Filter (Double Stage) | HEPA Filter having EU 13 rating with suitable size. | |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 14 | Pre Filter | Pureair” make, EU 4 rating with suitable size. |

| Efficiency | 90% down to 10 Microns. | |

| 15 | Noise Level | Less than 70 db ‘A’. |

| 16 | Vibration Level Instrumentation | Minimum. |

| 17 | Differential Pressure Gauge | Magnehelic Gauge – 01 No. (make : Dwyer, USA) with each unit (To measure differential pressure across the supply HEPA filter). |

| Motor Blower Assembly | Statically & Dynamically balanced with suitable rating and size. | |

| 18 | Supply & Exhaust | (Induction motor with centrifugal blower) A Mounting unique spring suspension system to take care of vibration and noise. |

| 19 | 3 Pins Switch & Socket | 15 AMPS – 1 set in each unit. |

| 20 | Other Switches | On/Off switches for motor blower & CFL lights. |

| 21 | Microprocessor Control | Airflow display and UV Interlocking and Low airflow Alarm and Supply & Exhaust filter Fail |

- Biosafety Cabinet Used in Laboratory

- Types Of Biosafety Cabinet

- Biosafety Cabinet Class 2

- Biosafety Cabinet Class 1

- Biosafety Cabinet Class 2 Price

- Biosafety Cabinet Class 3

- Biosafety Cabinet Class 2 type A2

- Biosafety Cabinet Class 2 Specifications

- Biosafety Cabinet Class 2 Function

- Biosafety Cabinet for chemotherapy

- Biosafety Cabinet Class 1 , 2, 3

- Biosafety Cabinet Class 4

- Biosafety Cabinet Class 3 Function

- Biosafety Cabinet Class 3 Specifications

- Biosafety Cabinet Class 2 B2

- Biosafety Cabinet Class II , type B2 Specifications

- Bio safety Cabinet Class II A2

- Biosafety Cabinet Class II B2

- Bio Safety Cabinet Manufacturers

- Biosafety Cabinet Suppliers